What Is EMC and Why Is It Important for Phones?

Do many people have questions about what Is EMC? Whether most people have heard of it or understand it, EMC is vital for our phones and daily lives. But what is EMC, and why is it important? We answer that question and more in our brief guide below.

Table of Contents

What Is EMC?

EMC stands for electromagnetic compatibility and is the interaction of electronic equipment with the electromagnetic environment and other equipment. Some people may not realize that all electronic devices can emit a small but disruptive electromagnetic field if unchecked with barriers and shields.

This electromagnetic field is due to the natural relationship between electrical flow and magnetism and isn’t the fault of malfunctioning equipment. Naturally, we can’t have all the electronic devices that make up our modern world interfering with one another, so our devices undergo EMC testing to ensure that they can function correctly.

Is EMC Different From EMI?

EMC and EMC testing are sometimes used interchangeably with electromagnetic interference (EMI), but they differ. The difference between EMC and EMI is that EMI is the actual energy that disrupts the operation of surrounding electric devices. This is typically from the electromagnetic field of another electrical device but sometimes from natural EMI.

Practically all man-made devices can cause EMI, including:

- Cell phones

- Microwaves

- Radios

- Wi-Fi devices

- Power lines

- Computer circuits

- And more

EMC and EMC testing refers to the ability of the electronic equipment to block out EMI or function under minor effects.

Why Is EMC Important for Our Phones?

Anyone who understands what EMC is would understand that EMC is important for our phones to function properly. EMC testing ensures that the vital electronic devices we depend on for communication can block EMI or withstand its effects.

Before a product, like an electronic consumer device, can be released, it must undergo rigorous EMC testing to ensure it can block EMI and understand how it responds to instances when it might see an increase in EMI. Without adequate EMC testing, an electronic device can prove unreliable. There have been many examples of phones and other devices being pulled from shelves because they didn’t undergo enough EMC testing and malfunctioned in the real world.

We hope our brief guide has helped clear up EMC, EMI, and their roles in our modern world full of electronics. If you have a phone constantly dropping calls or malfunctioning, it could be due to insufficient EMC testing and EMI.

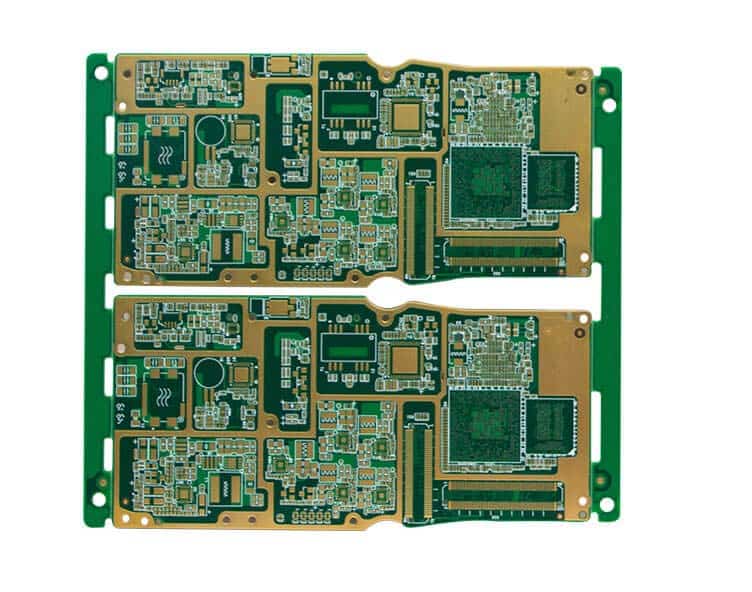

A Look into the Bindings Holding a Smartphone PCB Together

Smartphones have evolved into incredibly compact and powerful devices, with every component meticulously designed and arranged to maximize functionality and space. One critical element that often goes unnoticed but plays a crucial role in holding everything together is the binding, otherwise known as “glue.” This article will explore the fascinating world of the binding that secures a smartphone’s Printed Circuit Board (PCB) in place.

Role of Binding a Smartphone PCB

Inside every smartphone lies a complex labyrinth of electronic components, and the PCB serves as the central nervous system. It is a thin board made of insulating material, such as fibreglass or epoxy, with intricate copper traces that connect various components like the processor, memory, and sensors. Manufacturers rely on binding materials to keep these delicate components in place and ensure the PCB functions seamlessly.

Types of Binding Materials

Adhesive Films:

In modern smartphone manufacturing, adhesive films have gained popularity as binding materials. These thin, flexible films are made of a variety of materials from specialist polymer companies like Polymer Chemistry Innovations. They are precision-cut to match the shape and size of the PCB and other components. Adhesive films offer excellent heat resistance and durability while maintaining a low profile, making them ideal for compact devices like smartphones.

Liquid Adhesives:

Liquid adhesives, such as epoxy or polyurethane, are used to secure critical components like the CPU and RAM chips to the PCB. Manufacturers apply these adhesives in controlled amounts to ensure a strong bond without excessive weight or bulk. Liquid adhesives can withstand extreme temperatures, ensuring the smartphone’s longevity and performance.

Thermal Interface Materials:

To dissipate heat generated by the smartphone’s processor and other components, thermal interface materials are used as bindings. These materials, often in the form of thermal pads or greases, improve heat transfer between the components and the smartphone’s chassis, preventing overheating.

Functions of Binding Materials

Structural Support:

Bindings hold the PCB firmly in place, preventing it from shifting or flexing during use. This stability is essential for maintaining electrical connections and preventing damage to delicate components.

Shock Absorption:

Smartphones are prone to drops and impacts. Binding materials can also provide a degree of shock absorption, protecting the fragile PCB and preventing components from becoming dislodged.

Heat Dissipation:

As smartphones perform increasingly demanding tasks, heat management is crucial. Some binding materials are engineered to assist in heat dissipation, ensuring that the PCB and its components remain within safe operating temperatures.

Protection from Moisture and Dust:

Bindings can also act as a barrier against moisture and dust, safeguarding the PCB and sensitive electronic components from environmental damage.

Binding Technologies Innovations

Manufacturers continually seek to improve the binding materials and techniques used in smartphones. As smartphones become thinner and more feature-packed, the need for robust and efficient binding solutions becomes even more critical. Some innovations in this field include:

Nanotechnology: Nanomaterials are being explored for their potential to enhance the adhesive properties of binding materials while reducing their thickness. This allows for even thinner and more compact smartphones without compromising structural integrity.

Biodegradable Bindings:

In line with environmental concerns, some manufacturers are exploring biodegradable or eco-friendly binding materials to reduce the environmental impact of smartphone production and disposal.

In conclusion, while the binding holding a smartphone PCB together may go unnoticed, it plays a vital role in the overall performance and durability of the device. It ensures that the intricate web of components on the PCB functions seamlessly, even in the face of everyday challenges such as drops, temperature fluctuations, and moisture exposure. As technology continues to advance, expect to see further innovations in binding materials that make smartphones even more compact, durable, and environmentally friendly.